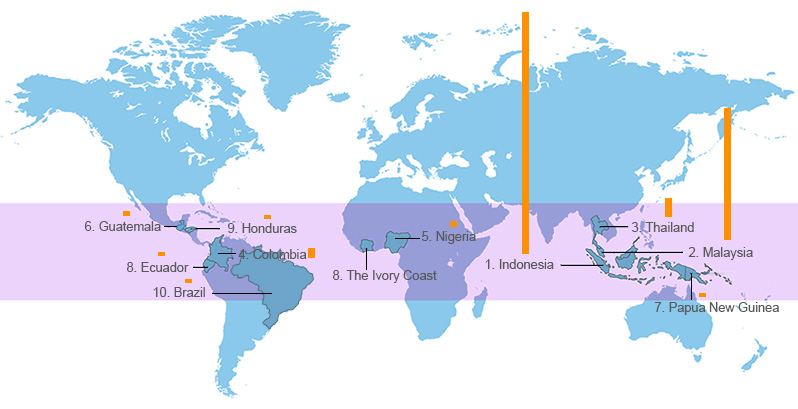

Oil palm, a kind of palmaceous plant, is mainly between the SL 5~10° and NL 5~10°. It a kind of important tropic oil seed plant with high economic value. At present, the palm oil is not only popular for edible oil, but also the important source of biodiesel.The main production area of palm oil is: Indonesia, Nigeria, Thailand, Columbia, Cote d’Ivoire, Papua New Guinea, Honduras, Ecuador, Brazil etc.

2018 Palm Oil Production by Country | ||

|---|---|---|

| Rank | Country | Production (1000 MT) |

| 1 | Indonesia | 40,500.00 |

| 2 | Malaysia | 21,000.00 |

| 3 | Thailand | 2,900.00 |

| 4 | Colombia | 1,530.00 |

| 5 | Nigeria | 970.00 |

| 6 | Guatemala | 740.00 |

| 7 | Papua New Guinea | 630.00 |

| 8 | Ecuador | 610.00 |

| 9 | Honduras | 580.00 |

| 10 | Brazil | 525.00 |

Bright Future of Palm Oil Processing Industry in Nigeria

Technology and energy has been the main focus of the world’s development today, therefore, those who have invested in agriculture now have made good profits and their earnings still keep increasing. Although agriculture business bring great profits for many entrepreneurs, few of them dare to venture into one segment - that is palm oil business.

Oil Production Market in Nigeria | |||||||

| Oil | Palm Oil & Palm Kernel Oil | Soybean Oil | Rapeseed Oil | Sunflower Seed Oil | Peanut Oil | Cottonseed Oil | Others |

|---|---|---|---|---|---|---|---|

| Market Share | 32.0% | 22.4% | 13.1% | 8.0% | 2.1% | 2.7% | 19.7% |

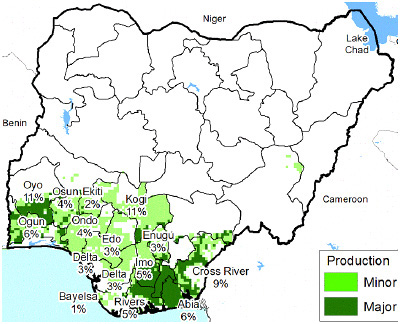

Nigeria was the largest palm oil market between 1950s to 1960s. At that time, its palm oil production had exceeded its domestic consumption, and the exceeded part was exported to the world’s market. However, the development of palm oil production was adversely changed after that. There were three main factors that had great impact on the development of palm oil processing mill in Nigeria:

- The discovery of petroleum deposit in Nigeria

- Nigeria civil war

- Traditional and out-of-date palm oil processing machines and techniques.

As a result, Nigeria is no longer the leader of palm oil production in the world. It has been outpaced by Indonesia and Malaysia.

However, the lower palm oil processing or production ability can’t match the increasing demand of palm oil, which now provides great opportunity to tap and expand the palm oil processing field in Nigeria and make profits from it.

Setting Up a Palm Oil Processing Mill in Nigeria

According to World Rain-forest Movement, oil palm was originally planted in the the Nigerian coastal plain and later was migrated to other inland places. So, oil palm is the most important crop in Nigeria. Setting up a palm oil processing mill in Nigeria would minimize the cost on raw material purchase and transportation. What’s more, Nigeria has great demand of crude palm oil. It would be very convenient to produce and sell palm oil in Nigeria, which must be a profitable business.

Total Cost of Setting Up a Palm Oil Mill in Nigeria

How much it will cost to set up a palm oil processing mill in Nigeria? Generally, the total cost of establishing a palm oil processing mill plant will be decided by many factors, including: the palm oil processing capacity, the quality and quantity of palm oil processing machines and equipment, the palm oil suppliers and more. Therefore, the exact cost of setting a palm oil processing mill plant in Nigeria would vary from the different requirements and specific situations. The following data is just for reference:

A complete palm oil processing mill plant with a capacity of 50 ton/day is about $ 60,0000, while a full complete palm kernel oil production line with capacity of 10 ton/day is $ 60,000 around.

Note: The exact cost of starting a palm oil milling business in Nigeria depends on the capacity requirments, process design and equipment configuration.

How to Calculate the Capacity of Palm Oil Mill You Need?

Palm Oil is concluding the Fresh Palm Fruit Oil and Palm Kernel Oil. Generally, whatever you want to build the oil plant from fresh fruits or from kernel, you can calculate the capaicty as the following steps:

- The oil palm grows very fast, it can harvest fruits about 2~2.5 years after transplanted.

- Per-hectare land should plant about 140 palm trees in general, each palm tree can produce about 20 tons fresh palm fruits annually.

- Basic the real running condition of the plant, 12.5% of orchard output are defined maximum consumption of raw material each mounth.

- The producing time should be caculated according to 25 days each month. Working time should be 20 hours one day.

For example, th palm oil plant capacity for 2000 hectares plantation or orchard is calculated as follow:

2000 x 20 x 12.5% / 25 / 20 = 10 ton/hour

2000 x 20 x 12.5% / 25 / 20 = 10 ton/hour

Common Palm Oil Mill Process In Nigeria

Small scale and medium scale production factories show great economic benefits.

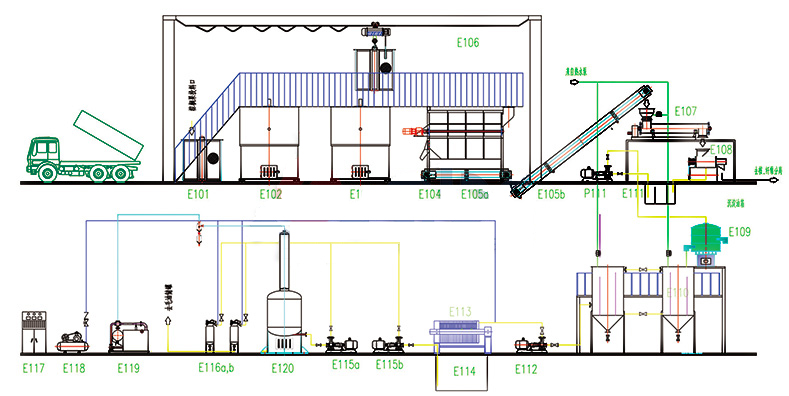

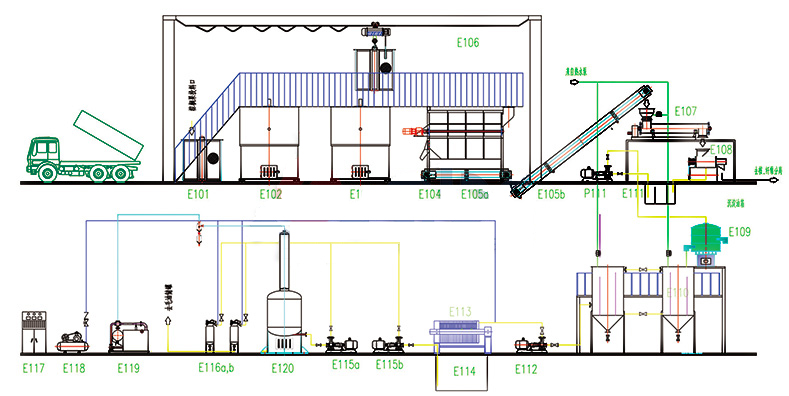

Small to Medium Sized Palm Oil Mill Plant Flow Chart

The typical processes to produce palm oil include palm bunches reception, palm bunches sterilization, palm threshing, palm fruit digestion, palm pulp pressing, palm oil clarification, palm oil drying and palm oil storage and packing.

- Palm Fruit Reception - Harvest the palm fruit from the oil palm plantation and remove the fruitlets

- Palm Oil Sterilization - Use water or steam t for palm fruit sterilization

- Palm Oil Threshing - Separate the palm fruitlets from the bunches by rotation or vibration

- Palm Oil Digestion - Crush the palm fruit to maximize the oil rate

- Palm Pulp Pressing - Utilize palm oil processing machines to extract palm oil

- Palm Oil Clarification - Remove foreign impurities from the final palm oil to get the crude palm oil

- Palm Oil Storage - The final crude palm oil will be stored in specialized tank for further selling or transportation.